Packaging engineering

ITENE helps to identify and design optimised packaging systems for logistics processes to ensure that loads stay safe throughout the entire transport chain.

ITENE identifies and quantifies transport chain risks using data recording devices fitted to delivery vehicles. This route-feature information is subsequently used to run transport simulation tests in our labs which realistically replicate the delivery route.

Packaging design and optimisation technologies

At ITENE we identify, design and optimise packaging systems to enhance solutions:

-

We examine the packaging used by the company to pinpoint critical issues, bearing in mind product and transport needs. We then suggest solutions for technical, economic and environmental improvements.

-

We design optimised packaging solutions for new products or to improve existing packaging systems due to over- or under-packaging.

-

There are several testing protocols, but Amazon’s is one of the most widely used. At ITENE we validate Amazon vendors’ packaging which has to comply with the Frustration Free Packaging programme’s requirements.

-

We help you standardise dimensions and technical specifications for all product families to minimise your company’s packaging SKUs as much as possible.

-

We design and develop packaging solutions by leveraging eco-design principles and methods. Our solutions comply with the environmental requirements of EU Directive 2018/852 to minimise their environmental impact.

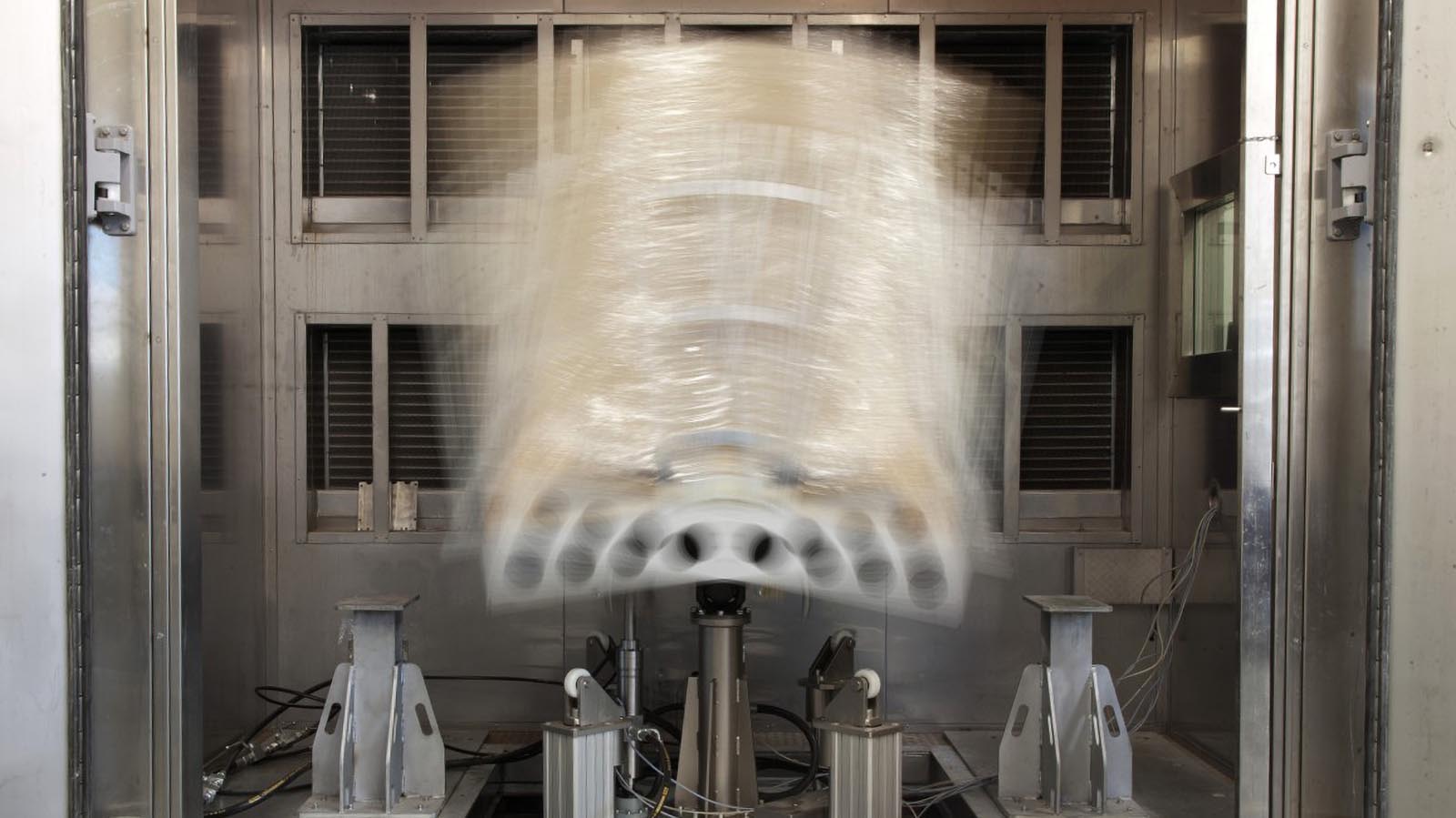

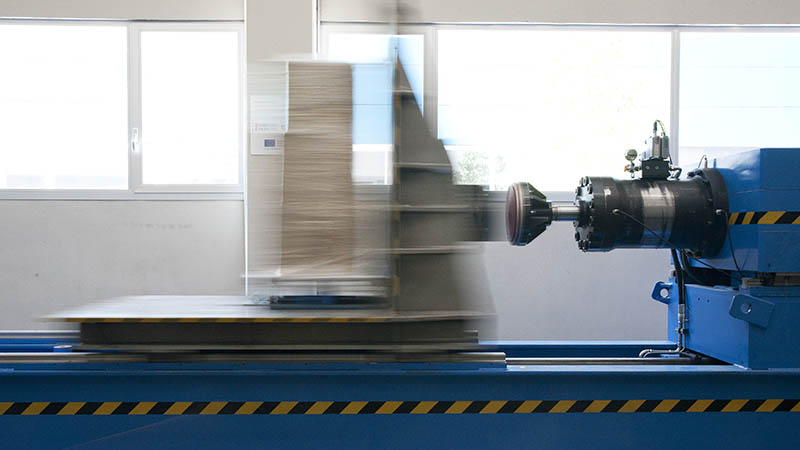

Packaging system validation technologies

At ITENE we replicate transport risks in our labs to improve packaging protection and optimisation and thus reduce incidents and cut costs during goods handling and delivery.

-

We compile and analyse the linear accelerations, angular velocities and shocks specific to the target delivery route, which may include loading and unloading operations on dispatch and at intermediate stages up to the final destination.

We do this using a data recorder which can quantify mechanical risks (vibrations, shocks, impacts) alongside other atmospheric devices to measure temperature and relative humidity.

-

We follow standards such as the ASTM and ISTA protocols, and tailor test severity to the company’s previously described route with a data recorder developed by ITENE to validate the optimised packaging systems.

-

At ITENE we assess whether your company complies with the guidelines laid down by Royal Decree 563/2017 and the associated UNE 12195-1:2010 and EUMOS 40509 standards about packaging and stowage of loads in road and maritime transport.

Our consultancy services cover four stages: audit, specification of upgrading protocols, load stability appraisal and employee training.

Benefits of packaging engineering

- Makes the company more competitive.

- Reduces losses due to transport incidents.

- Cuts costs from over-packaging.

- Product quality assurance at the time of delivery to the consumer.

-

Could I help you?

Ariana Gómez

Head of Packaging Systems Testing Laboratory