Packaging waste collection, transport and sorting

Compliance with the objective of recycling 65% of all packaging by 2025 as set out in Directive 2018/852 on Packaging and Packaging Waste will first require efforts to improve selective packaging-waste collection to increase the quantity and quality of the waste to be treated. Measures can also be applied in the transport phase to reduce the carbon footprint and raise sustainability standards.

Improving the sorting processes of the various packaging materials is also essential, especially of those that are not currently recovered. At ITENE we develop new processes and technologies for all of these phases.

Technological solutions to improve waste collection, transport and sorting

1. Waste collection

Ascertaining the quantity and quality of the waste generated by each citizen will enable us to provide a differential service to local governments and to raise the quality of the fractions obtained after the sorting process. This will also encourage recycling and raise public awareness. ITENE develops the following technologies to enhance the collection process:

- Smart containers.

- Payment for recycling waste.

2. Transport

Monitoring waste container conditions according to parameters such as filling level, waste degradation and implementing a route-planning system optimise waste collection and transport. This reduces costs and minimizes the carbon footprint via a series of mechanisms such as:

- Equipping containers with sensors.

- Optimising collection routes.

Succes Story

The deployment of 25 smart containers in the San Marcelino district of Valencia enabled waste collection trucks to achieve the following reductions:

- 41% Less distance travelled.

- 32% Less time devoted to collection.

- 22% Less fuel consumed.

These results were achieved within the framework of the European PLASTICIRCLE project funded by the European Union and coordinated by ITENE. Learn more about the PLASTICIRCLE project.

3. Sorting

The identification and sorting of materials in waste treatment plants, improvements in the quality and separation of specific material streams and the identification and tracking of the packaging journey in waste treatment plants enables the following activities:

- Study of the behaviour of materials and packaging and impurities in post-use fractions.

- Generation of cleaner waste streams, creation of ad-hoc recycling circuits, improvement in the quality of recovered material flows and separation of high added-value packaging.

- Collection of data on plant operation and sorting processes.

- Analysis of the recyclability and design of certain types of packaging.

Various strategies are implemented to achieve this:

- Material detection and separation processes.

- Separation of ferrous and non-ferrous metals.

- Advanced markers to separate material flows, according to their type and source.

- Identification of packaging streams via RFID systems.

https://www.youtube.com/watch?v=jZ1pPIR3e4o&list=PLJ3IMWZ0eQx0XlATMAFWnxCql1wTSMi-H&index=3

Succes Story

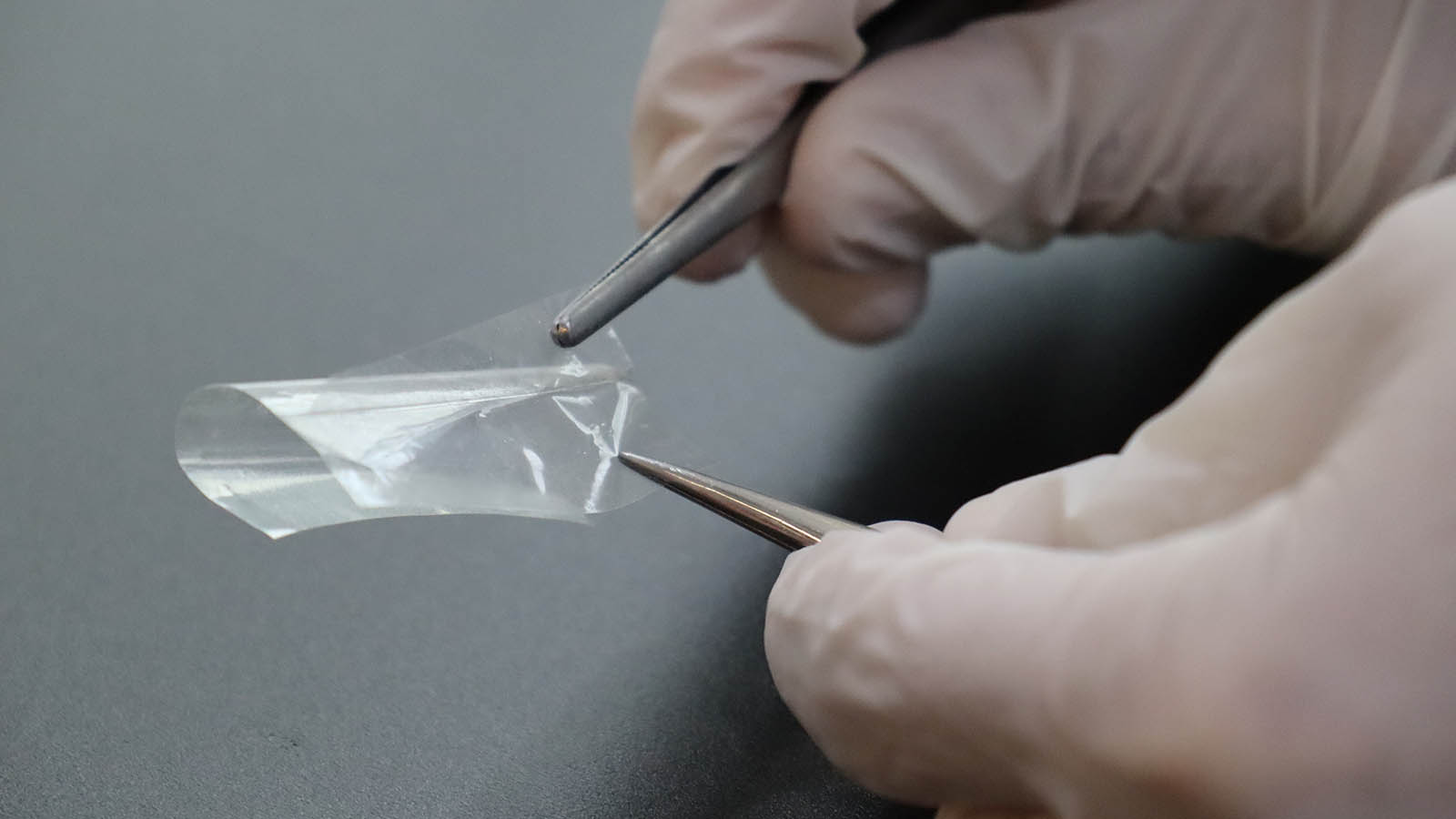

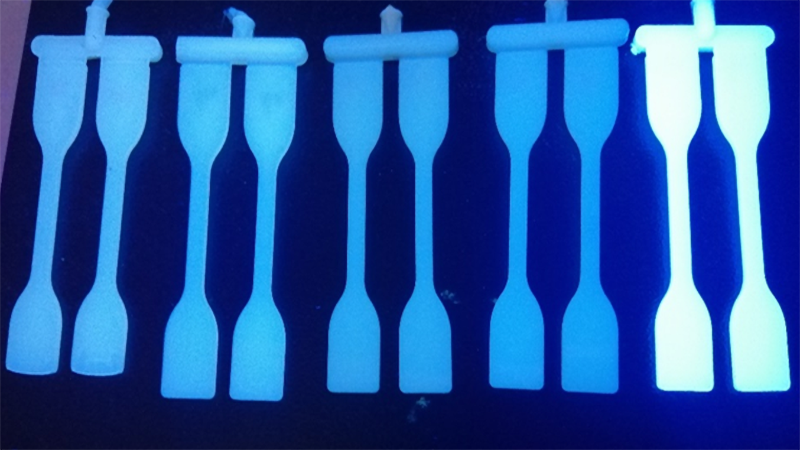

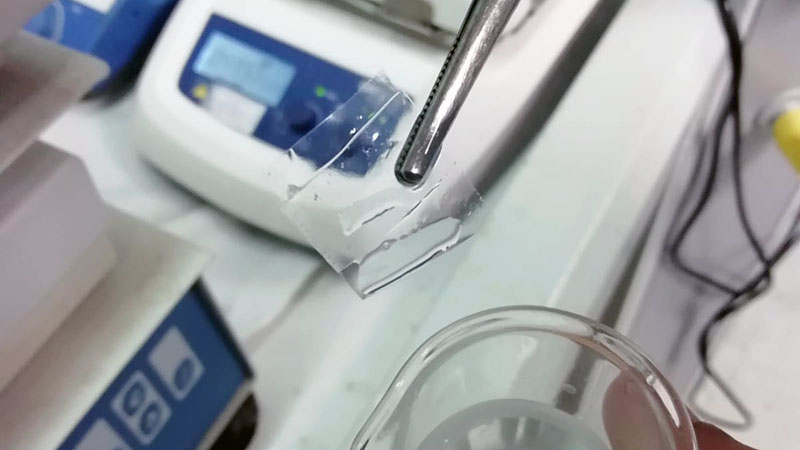

ITENE has managed to separate multilayer plastic packaging from other types of packaging in the general waste influx at sorting plants thus generating purer streams.

This was achieved thanks to the identification of a compound which, in very low concentrations, detects this packaging using ultraviolet-visible optical technologies.

This compound has been tested with various polymeric matrices and has responded extremely well in all of them.

-

How can I help you?

César Aliaga

Head of Packaging and Circular Economy Unit