Active packaging to extend product shelf-life

Active packaging interacts with the product it contains either by releasing substances that have a beneficial effect on the food or its environment, or by absorbing substances that could accelerate its deterioration. In both cases, the result is longer shelf-life and enhanced product quality. This kind of packaging can also improve the consumers’ sensory experience.

At ITENE we develop active packaging for a range of areas such as the food, cosmetics and personal hygiene industries.

What kind of active packaging do we develop?

Active packaging according to the mechanism of action

ITENE develops active packaging that can help extend a product’s shelf-life in two ways:

- Controlled-release packaging: designed to release beneficial substances into the food or its environment (CO2, antimicrobial substances, antioxidants, etc.).

- Absorbent packaging: designed to absorb harmful substances from the food or its environment (oxygen, ethylene, humidity, carbon dioxide, etc.).

Active systems according to how they are integrated into the packaging

ITENE develops active systems that are integrated into the packaging in two ways:

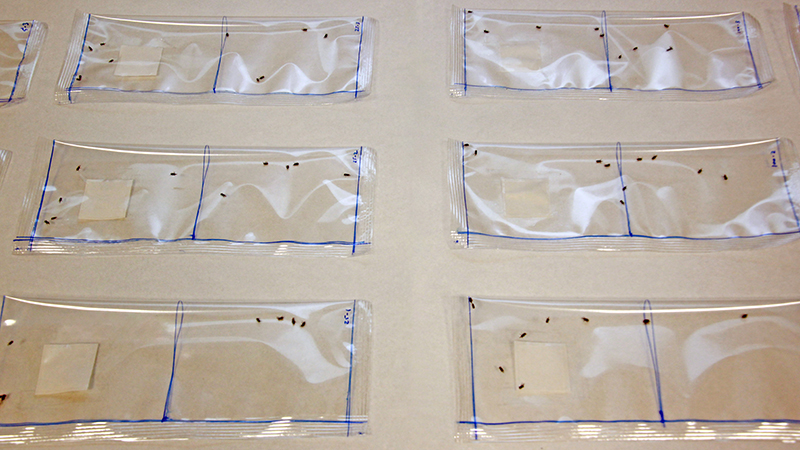

- Independent systems or devices: in this case, the active substance is inserted into an envelope, sachet or label that is subsequently put into the package, usually during the packaging process.

- In the packaging material: in this case, the active substance forms part of the actual packaging material. Extrusion techniques, mixing into the polymeric matrix, and coating application methods can be used to integrate the active substance.

Active packaging solutions developed by ITENE

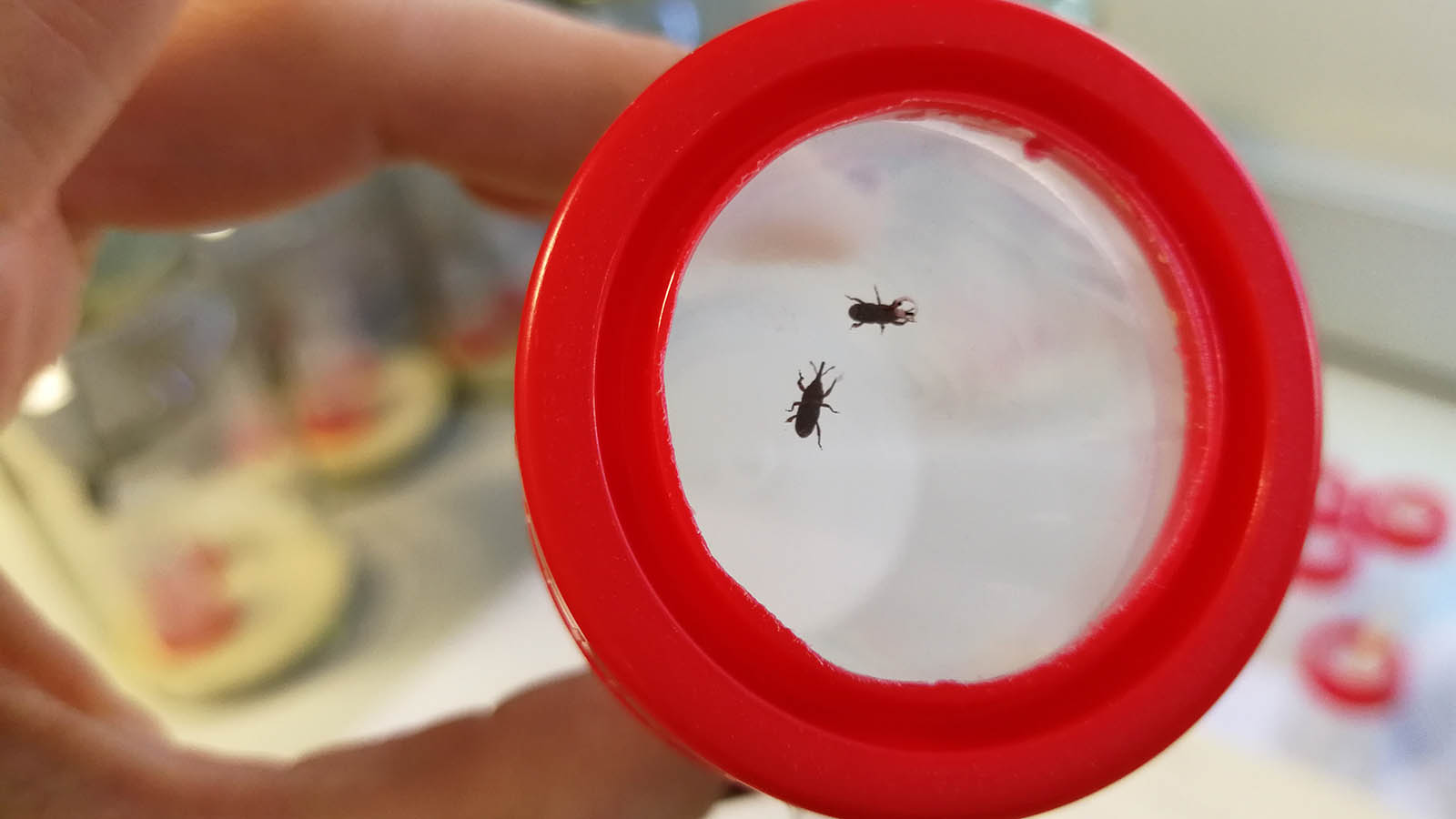

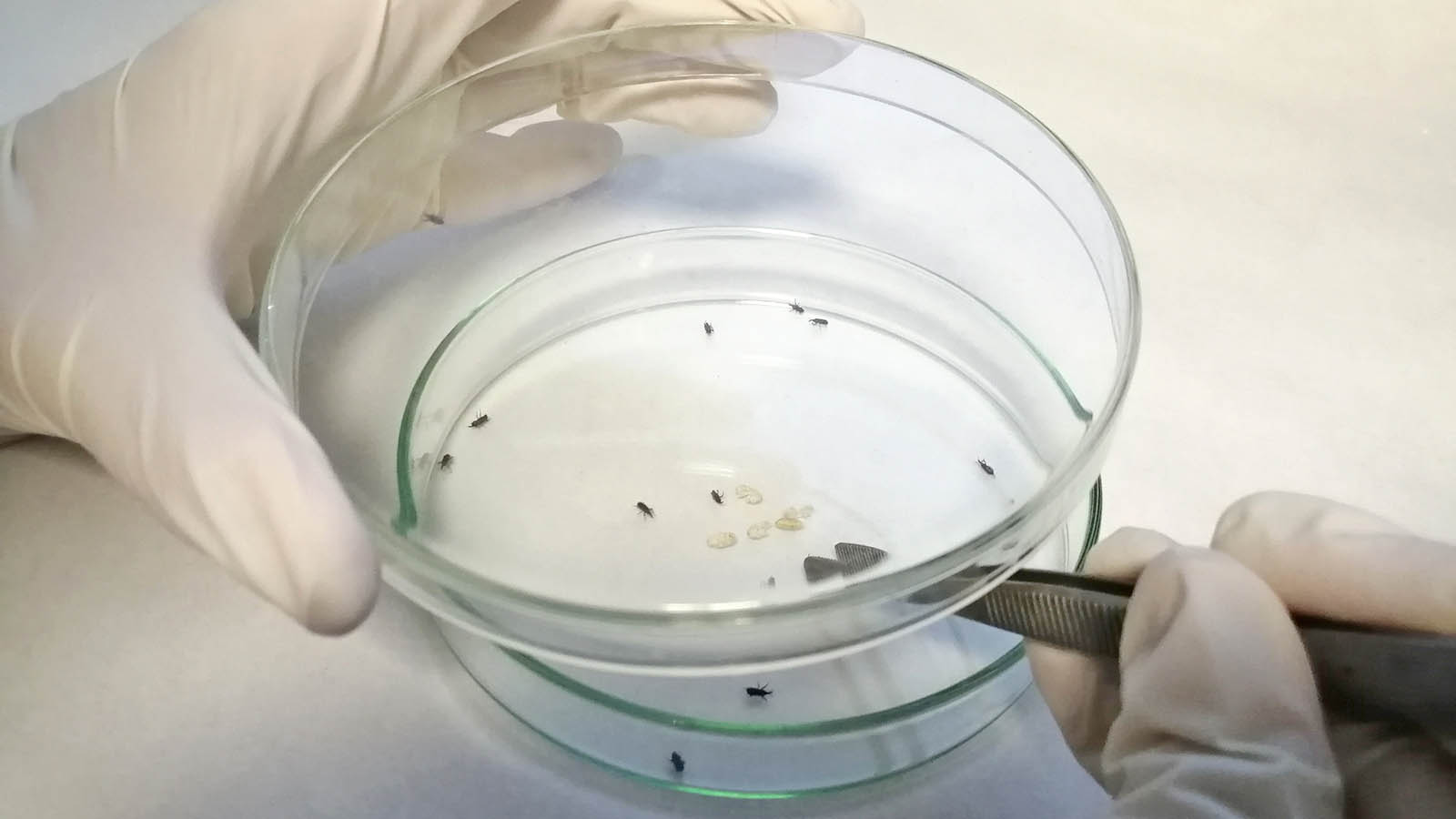

Active insect-repellent and moisture-absorbent packaging

New materials based on the application of insect-repellent and moisture-absorbent coatings on flexible packaging materials.

- Effectiveness in laboratory-scale trials is 80 to 90% better than other packaging materials used today.

- The solution is applicable by flexographic and gravure printing processes.

- Packaging materials have good transparency and good adhesive properties between the coating and the substrate.

Thanks to this project, in which the companies Plásticos del Segura and Pastas Alimenticias Romero participated, dry food products can be protected and preserved from infestations of pantry pests.

Find out more about the PASTA-ACTIVEPACKproject.

Other types of active packaging systems

- Active films with pest-repellent effect designed for dry food liable to infestation, such as rice and pasta.

- Packaging in a tray format with a double compartment to physically separate the food from active substances, thus preventing accidental contamination issues.

- Cellulosic materials for packaging and paper and cardboard packaging with antifungal action.

Find out more about the FOOD-REDUWASTE project.

Active packaging for packaged fresh fruit

Cardboard containers with active coatings with an antimicrobial function that prevents or retards the growth of spoilage microorganisms (fungi) for red fruit and sliced fruit.

Find out more about the FRUIT4U project.

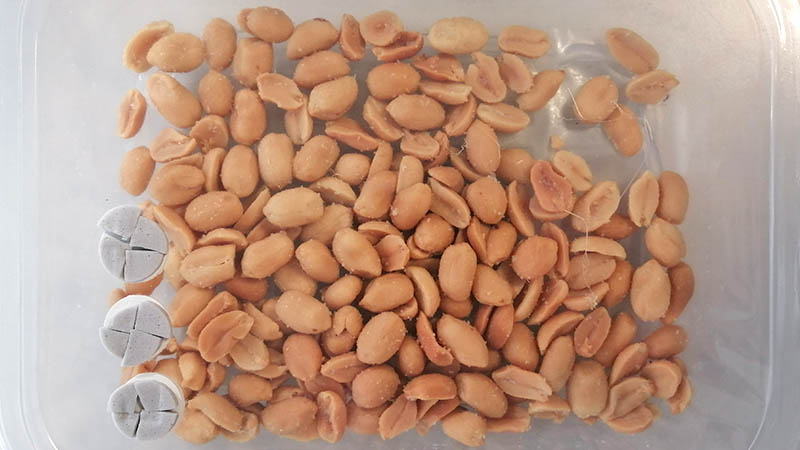

Active packaging solutions for dry products

Packaging materials consisting of two types of active films:

- Oxygen absorbers that prevent rancidity in high-fat products.

- insect pest-repellent agents.

Find out more about the OPTIDRY project.

Packaging that extends the shelf life of packaged fresh chicken

- Tray that can generate a modified atmosphere by harnessing the exudate from fresh chicken breasts. This solution enables the packaged product to retain optimum freshness for a longer period of time.

- A tray that releases substances with antimicrobial activity aimed at reducing contamination by campylobacter bacteria in fresh skin-on chicken, thus ensuring the microbiological safety of this type of product.

Find out more about the CHICKENPACK project.

What are the advantages of active packaging?

Active packaging is an advanced technological solution that provides an alternative to the use of conventional packaging systems. Its use entails a series of advantages that extend the shelf-life of the product:

- It helps to reduce food waste. Optimal food preservation brings increased shelf life, as the food remains at its highest level of nutritional and sensory quality for a longer period of time.

- As active packaging can release minimal doses of preservatives into the packaged product in a gradual, controlled manner, it enables consumption of more natural products by reducing or eliminating the use of preservatives.

- It creates safer products by reducing or eliminating the microbial population.

- It helps to improve logistics processes and provides access to more distant markets thanks to the increase in the product’s shelf-life.

-

How can I help you?

María Monedero

Project Manager