Nanotechnology

Nanotechnology is a key enabling technology (KET) and essential in product and process development across a number of industrial sectors. Nanomaterials (NMs) are especially relevant in this sense, and their approval, risk assessment and labelling requirements are set out in the EU regulatory framework.

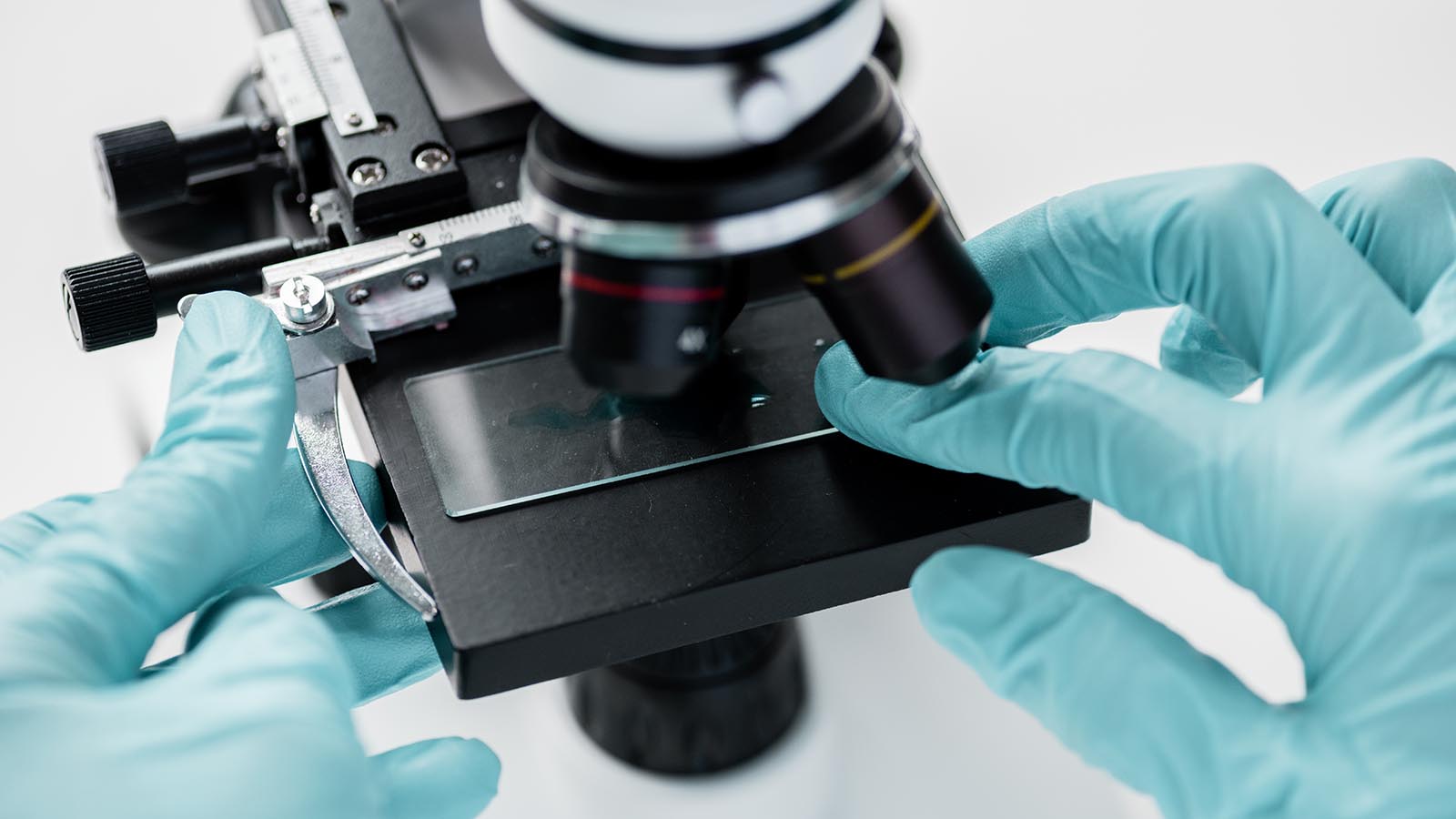

At ITENE we retrofit conventional material processing technology for nanotechnology materials and also use nanotechnology to obtain custom-made materials by modifying their properties. We additionally help businesses to work safely with nanotechnology.

Nanotechnology for advanced material development

What are nanomaterials?

The term ‘nanomaterial’ is used for a wide variety of materials which have very different compositions and properties yet also the shared characteristic that at least one external dimension of all or part of their constituent particles (more than 50%) is smaller than 100 nanometres. Nanotechnology may thus be thought of as manipulating matter at the nanoscale (1-100 nanometres).

Due to the higher specific surface area per volume unit that occurs in materials at nanoscale, their characteristics differ from those occurring in the same material at the non-nanoscale, which are not the same as their characteristics at atomic level. With only a small percentage, less than 5%, improvements of up to 30% in oxygen barrier properties or increased thermal resistance up to 15°C can be achieved.

How we use nanotechnology to improve materials

-

ITENE has wide-ranging experience in adding nanomaterials which brings businesses competitive advantages by developing high-performance materials with significant improvements in their mechanical, thermal and barrier properties and biodegradability. It also affords new options in product quality and active protection and preservation of packaged foodstuffs.

Some nanomaterials additionally exhibit characteristics of antimicrobial agents, antioxidants or biocatalysts or responsiveness to external stimuli by changing their conformation or solubility.

-

at ITENE we have several patents for nanomaterials which we have developed, including a PET (polyethylene terephthalate) nanocomposite with modified clay that improves this polymer’s barrier and mechanical properties.

-

Designing processes to obtain minimum quantities for industrial testing.

-

For large-scale nanomaterial synthesis.

-

-

Industry is increasingly keen on this non-toxic material as it is renewable, biodegradable and compostable, features which make it more appealing under the circular economy plan’s requirements.

-

Adding them to formulations to develop new biocomposites and coatings which improve the barrier, thermal and mechanical properties of biopolymers used in packaging applications.

Nanotechnology in safety and security

We also draw on nanotechnology in the area of safety based on regulations to analyse the risks of exposure in the workplace or release into the environment.

- REACH consultancy for nanomaterials. Setting up protocols and procedures for safe use of nanomaterials.

- Exposure assessment and estimation systems: ITENE has developed the NanoWatcher system, a portable device for sampling various processes, and the NanoDESK platform, which identifies nanomaterials, assesses the hazard and estimates exposure.

- Risk assessment and characterisation for decision-making and compliance with legislation. Quantitative assessment of occupational exposure to nanoparticles and ultrafine particles.

- Effectiveness testing of risk management measures: engineering controls and PPE.

-

How can I help you?

Natalia Ortuño

Project Manager