Packaging material formulation and processing

ITENE develops technologies for formulating and processing materials for a range of applications, mainly in packaging. We devise new materials with enhanced performance and new functionalities while ensuring they can be mass produced using conventional packaging industry equipment such as sheet and film extrusion through cast and single and multilayer blow molding, hollow body extrusion-blow molding, injection, injection-blow molding, thermoforming, coatings, lamination, and printing.

R&D to enhance polymeric and cellulosic material properties

Researching and developing new materials has enabled us to improve the characteristic properties of materials used for packaging and to bring new, more sustainable materials onto the market by:

- Drawing on alternative raw materials (obtained from renewable, bio-based and recycled polymers).

- Functionalisation through including additives.

- Designing advanced simulation methods for processing technologies (compounding) to optimise new material formulations for use in packaging.

ITENE researches and develops new materials to enhance their performance in packaging applications. All the materials we develop are tested with a view to their end use and mass production. They are engineered under recycling-by-design principles while bearing in mind their end-of-life in line with the European circular economy strategy and the Royal Decree on packaging and packaging waste. We also assess their safety in compliance with applicable legislation (food safety, material production safety, etc.).

We work to develop materials which have significantly superior properties compared to their conventional counterparts available on the market in terms of lower costs, greater sustainability, enhanced performance and increased functionalities for a range of applications.

Achieving this goal calls for seamless interaction between developing new material formulations (including additives), processing technologies, end-of-life and product validation. We make these improvements in the field of both plastic and cellulosic materials.

-

- Industrial and domestic biodegradable and compostable polymers based on certified polymers: polylactic acid (PLA), polyhydroxyalkanoates (PHAs), thermoplastic starch (TPS), biopolyester blends, etc.

- Conventional polymers, including polyethylene terephthalate (PET), polypropylene (PP) and polyolefins such as polyethylene (HDPE, LDPE, LLDPE).

- Recycled polymers, both polyesters and polyolefins.

- Bio-based polymers from renewable sources (BioPE, BioPP, BioPET, BioPA).

- Customised formulations.

-

We improve paper and cardboard to enhance their barrier properties against moisture, gases and fats, boost their mechanical resistance. We also use alternative sources of cellulosic materials to achieve this aim.

- Wood cellulose pulp, recycled pulp and pulp from waste or lignocellulosic by-products.

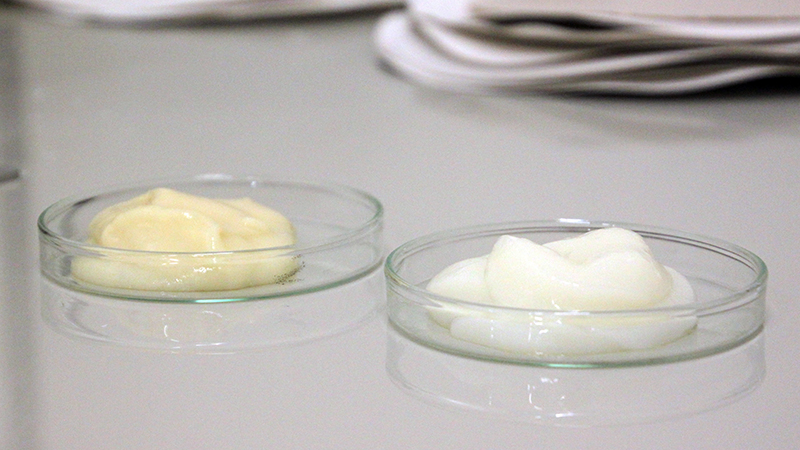

- Extraction and functionalisation of cellulose additives: microfibrillated cellulose (MFC), microcrystalline cellulose (MCC) and several types of nanocellulose.

- Moulded cellulose formulations.

- Formulations for paper, cardboard and paperboard.

Meeting the industry’s needs

- Complying with EU, national and regional legislation regulating packaging production and management.

- Enhancing or modifying properties by selecting components in the mixture or changing their proportions.

- Reducing raw materials, costs and environmental impact.

- Optimising packaging material properties to boost performance.

-

How can I help you?

Miriam Gallur

Materials and Packaging Area Manager