Sustainable inks, adhesives and functional coatings

The sustainability requirements that apply to packaging also apply to the ancillary materials that are used in it, such as inks, adhesives and coatings.

Bio-based inks ,that contribute to packaging biodegradability or compostability, can thus help to enhance their sustainability, recyclability and reusability.

Meeting the requirements of the circular economy:

Compliance with the 2030 European strategy states that inks, adhesives and coatings must follow the same criteria as packaging to demonstrate their overall sustainability.

-

- Using inks that are bio-based, biodegradable and compostable without any loss of print quality.

-

- Reducing layers or thicknesses in multilayer packaging.

- Making it easier to separate layers in multilayer packaging.

- Making it easier to empty packaging.

-

- Making it easier to empty packaging.

-

- Replacing multilayers with monolayers.

Sustainable ink solutions

Bio-based coloured inks that could prove to be fully biodegradable and compostable.

These inks have been validated at industrial level by partner companies with satisfactory results in terms of covering power and adhesion.

Advantages:

- They could be printed without weight limits, thus facilitating printing designs.

- They make it easier to obtain compostability certificates for the goods on which they are printed.

- They help to reduce the carbon footprint, the non-emission of volatile organic compounds and reduce the dependence on fossil fuels to obtain inks for the printing industry.

For the analysis of these inks, it was applied the ASTM D6866 Standard test methods for determining the biobased content of solid, liquid, and gaseous samples using radiocarbon analysis and the standard EN 16640 Bio-based products – Bio-based carbon content – Determination of the biobased carbon content using the radiocarbon method.

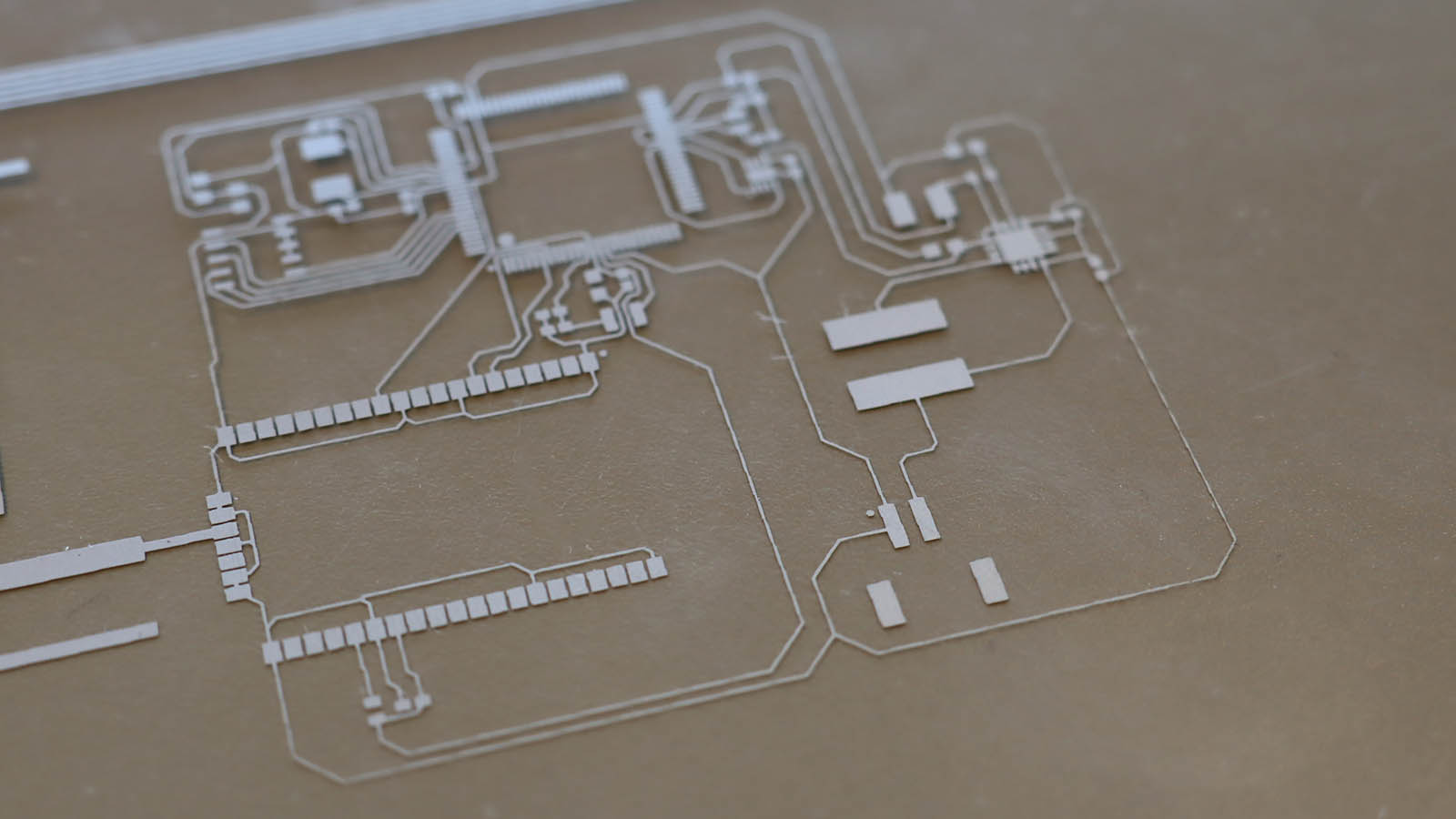

Microwavable printed susceptor ink for snacks and pre-prepared convenience food products

Susceptor ink based on compounds that facilitate food heating. This is a monolayer development based on a paper substrate that replaces aluminised PET.

Advantages:

- More sustainable solution and alternative to standard commercial susceptor packaging.

- Suitable for bakery, pastry, pizza products, etc.

- Suitable for use on substrates other than paper, which increases its usability for ready-to-heat products.

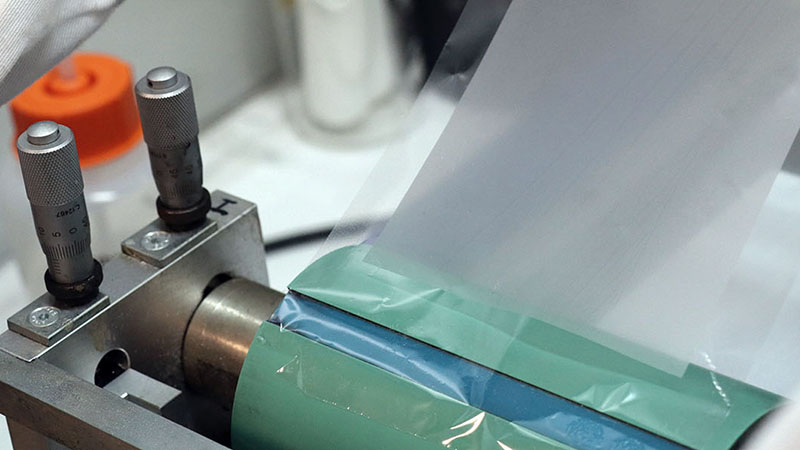

Adhesives to facilitate multi-layer packaging recyclability

The formulation of the adhesives has been modified so that they can respond to external stimuli which causes them to lose their bonding capacity, thus enabling layer separation.

This development paves the way for high-quality multilayer materials that only delaminate when certain stimuli are applied, which means that this can be controlled.

This solution also dovetails with existing recycling technologies, eliminating the need to modify current processes.

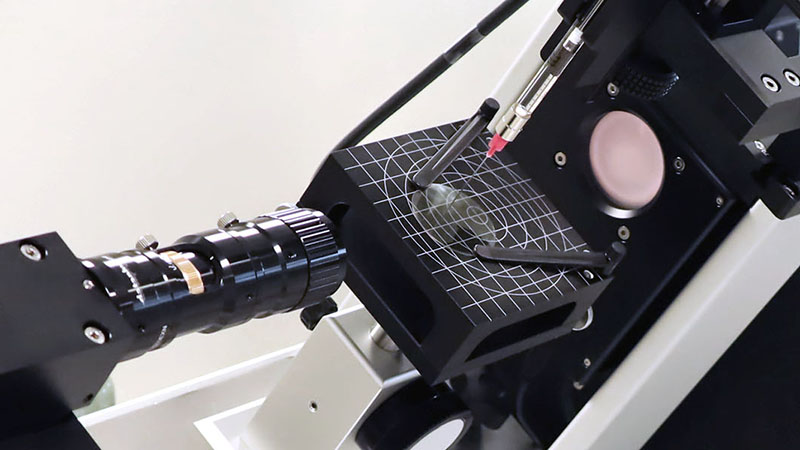

Functional treatments to make it easier to empty and recycle packaging

Strategies have been developed to chemically modify the surface of a material. This modification allows to lower the material’s free surface energy, among other properties, and can have a direct application to making packaging emptying easier, as well to as other related applications such as easy surface cleaning.

This surface treatment does away with laminates, varnishes and coatings and contributes to packaging recycling, as well as reducing food waste.

Download our brochure

-

How can I help you?

Jesús Palenzuela

Head of Printing technologies and Functional surfaces Unit