Packaging recycling processes

The European roadmap for promoting the circular economy requires the development of new processes for the recovery of plastic, paper and cardboard packaging waste. Generating high-quality material flows is an essential step towards homogenising the quality of the fractions, increasing the value of the bales of waste and, creating recycled materials which can compete with virgin material by means of waste recovery processes.

At ITENE we develop new plastic and cardboard recycling processes and mechanical, chemical and enzymatic recycling processes to recover plastic packaging or fractions. We then harness these innovations to provide technological solutions to help the packaging value chain to meet the sustainability objectives, which include increasing the percentage and quality of recycled packaging materials.

Why is it necessary to develop and implement new recycling processes?

European Legislation and Strategies

- Directive 2018/85. Objectives:

- Paper and cardboard packaging – 75% recycling by 2025 and 85% by 2030.

- Plastic packaging– 50% recycling by 2025 and 55% by 2030.

- Directive 2019/904. Reduction of the impact of certain plastic products.

- PET beverage bottles – At least 25% recycled plastic by 2025 | Up to 30% by 2030, and it also includes beverage bottles made from other plastic materials (e.g., PE).

- Green Deal. Circular Economy Action Plan 2.0 2020

- Extends the use of recycled plastic to other polymers besides PET

- Future Regulation on Packaging and Packaging Waste

- All EU packaging must be recyclable by 2030

- Reduction of packaging waste by 15% per person and Member State (compared to 2018) by 2040.

Spanish Legislation and Strategies

- Waste and Contaminated Soil Law for a Circular Economy:

- New special tax on non-reusable plastic packaging – January 2023.

- Reduction of waste weight by 13% (compared to 2010) – 2025 and 15% reduction – 2030.

- Producers must take total or partial responsibility for organizing waste management and use materials from waste in product manufacturing.

- Limits on single-use plastics: 50% reduction in weight usage (compared to 2022) – 2026 and 70% reduction – 2030.

- Royal Decree on Packaging and Packaging Waste:

- All marketed packaging must be recyclable and, where possible, reusable – 2030./li>

- 20% reduction in single-use plastic bottles (compared to 2022) in 2030.

Recycling paper and plastic

We are working to develop and adapt technologies to improve the recycling process to obtain a new material of high quality and added value. These innovations enable us to tackle the following challenges:

- Helping recycling plants to improve their recycling processes.

- By improving these processes, we help to make certain packaging recyclable and therefore enable companies to:

- Validate the recyclability of packaging by means of specific laboratory trials (ATICELCA or INGEDE).

- Demonstrate that their packaging is adapted to comply with the recyclability targets of 75% of all paper and cardboard materials contained in packaging waste by 2025 and 85% by 2030.

- Develop new improved cellulosic packaging solutions that make new features (e.g., enhanced product protection by coatings or laminates) compatible with recyclability.

-

We improve the decontamination processes to obtain a higher quality recycled paper. In doing so, ITENE helps companies to:

- Comply with legislation on recycling and material recovery.

- Increase the quality of the recycled fibre by eliminating contaminants such as mineral oils, PFA and BPA, among others.

- We develop solutions to avoid chemical risks (migration of additives or contaminants), microbiological risks (favourable humidity and pH conditions; aqueous and/or fatty foods, etc.) and organoleptic risks (altered odour and flavour conditions).

-

We adapt and develop technologies to achieve fibre disintegration in the pulping process, with a special focus on laminated or coated papers. These solutions allow us to:

- Support companies that use new paper and board laminate developments and have to demonstrate that they are recyclable by methods such as CEPI and ATICELCA.

- Provide recycling companies with new solutions to optimize their recycling processes.

- Offer technological solutions to help meet paper and board packaging recycling targets (75% by 2025 and 85% by 2030):

- We define proposals for the improvement of the recyclability of packaging and paper and board products.

- We evaluate the efficiency of recycling processes (process yield and reject production) and propose new solutions to optimise recovery processes.

- We evaluate and improve the quality of recycled paper (optical, physical and mechanical properties).

-

We adapt and optimise the de-inking processes to solve the difficulties caused by the presence of inks in recovered paper, especially when it is going to be used in food packaging. At ITENE:

- We evaluate the de-inkability of packaging and paper products during the recycling process using methods such as INGEDE 11.

- We optimise de-inking during the pulping process (residence time, reagents, agitation, temperature, etc.).

- We evaluate and improve the quality of the de-inked paper (mechanical and optical properties).

Recycling plastic

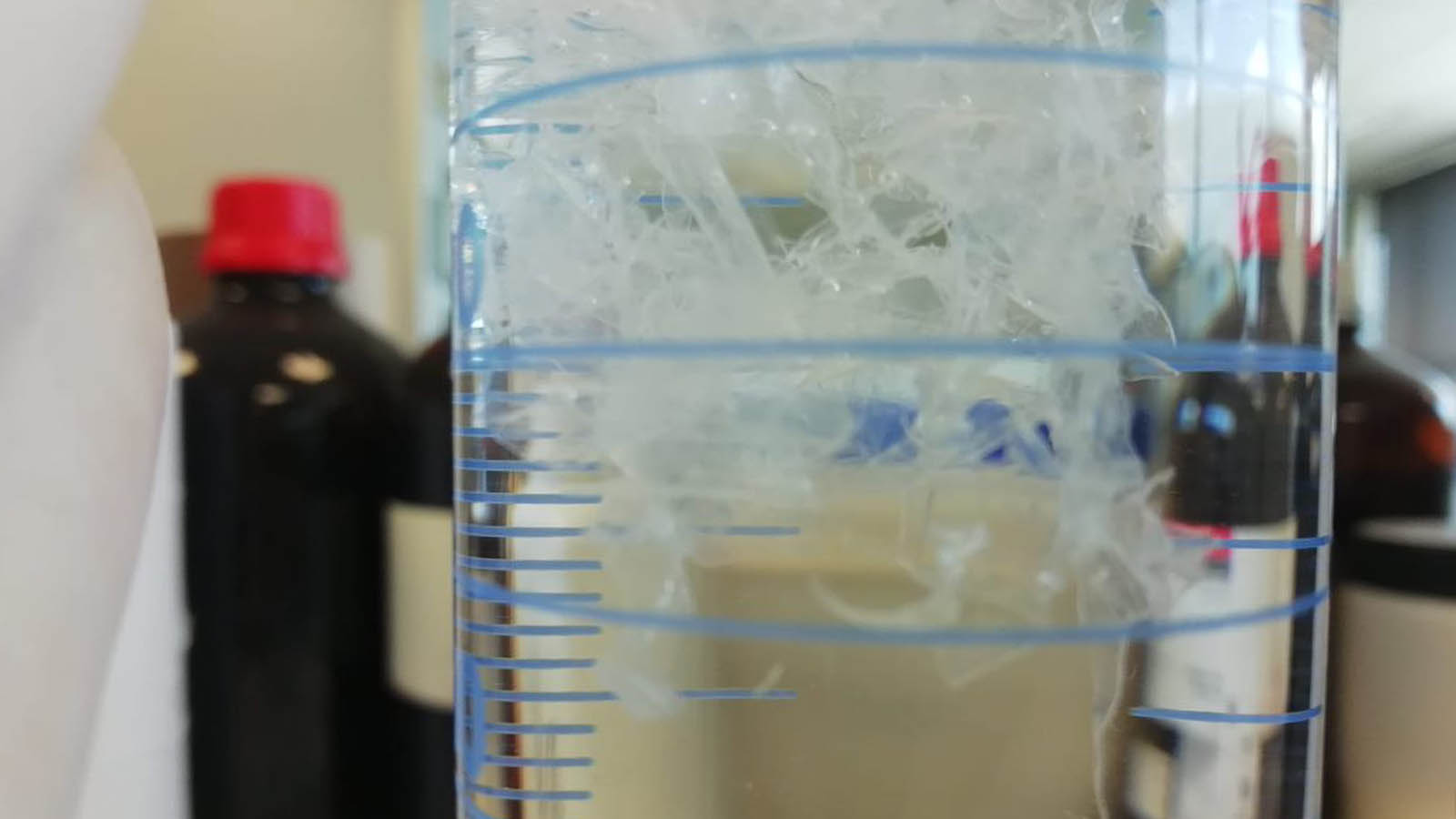

Waste pre-treatment

Pre-treatment of waste is the preliminary stage to any recovery process. Its purpose is to condition the fraction to be recovered in order to obtain a clean, heterogeneous fraction that can be suitably dosed and protects the equipment used during recovery.

At ITENE we design pre-treatment processes and optimise operating conditions in order to raise the quality of the recycled materials:

- Waste characterization.

- Separation and classification of materials.

- Crushing and grinding.

- Washing, flotation, and drying.

- Decontamination and odor removal (water vapor, supercritical CO2, solvent treatments, and ozone).

- Delamination (selective dissolution and depolymerization).

- Deinking.

Mechanical recycling

Mechanical recycling generally consists of inserting plastic waste – previously subjected to a pre-treatment process – into an extruder to obtain recycled pellets that can be transformed into new products.

However, plastic waste has a number of limitations when it comes to recycling, which are primarily due to its usually poorer properties and potential processing difficulties caused by:

- The presence of contaminants originating in the packaging and collection, classification and recycling use phases of the material or in complex or multilayer structures.

- Degradation derived from some prior process, from the use given to the material or even the recycling process itself.

For the improvement of these processes and the use of recycled plastics in high-value-added applications, ITENE is working on research in new technologies such as:

- Development of nanometre-scale inorganic additive modification processes to improve their compatibility with recycled plastic materials and consequently the properties of the final product.

- Reactive extrusion: a continuous process which uses an extruder as a chemical reactor that acts as a vehicle to carry out chemical melt reactions and produce recycled polymers with improved properties rheological, mechanical, and chemical.

In turn, these enhancement methods are based on:

- Design of specific screw configurations for the optimisation of additive and reinforcement dispersion or reactive extrusion processes, thus improving the performance of recycled plastics in extrusion processes.

- Online rheology: assessment of the viscoelastic properties of the plastic materials recycled during the extrusion process for in situ adjustment of the process parameters and the additive or reactive extrusion route.

Chemical recycling

Chemical recycling is proposed as an innovative solution, complementary to mechanical recycling. It allows addressing different routes and recycling processes aimed at the current, more complex fractions to valorize, using:

- Techniques focused on the selective breaking of the polymer chain, through depolymerization processes by solvolysis, obtaining the starting monomers.

- Chemically valorizing plastic materials through pyrolysis and gasification for their subsequent upgrading to products of interest in the chemical industry.

Solutions to improve chemical recycling processes

-

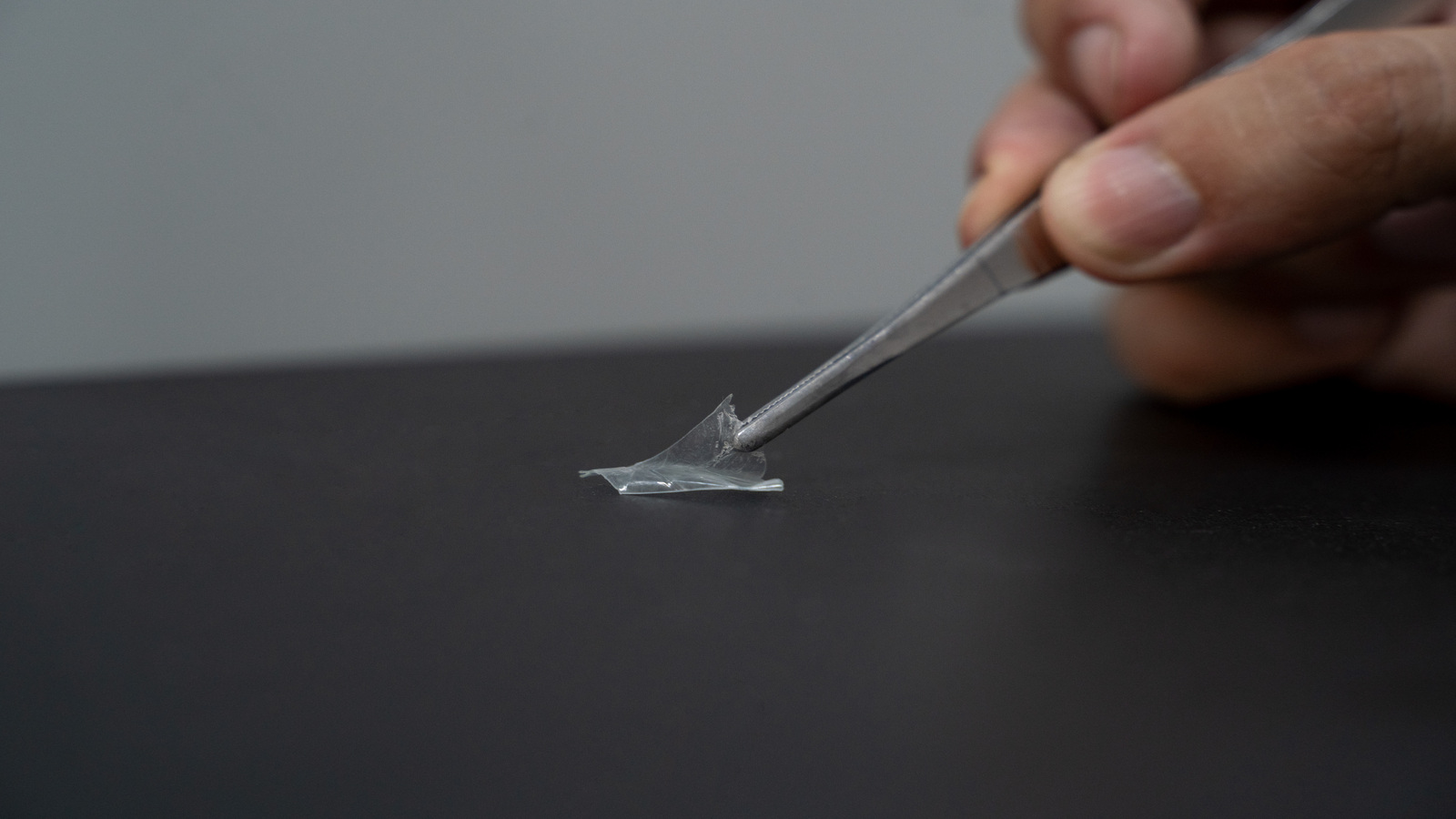

We are developing new delamination processes to achieve effective separation of the layers that make up a multilayer structure by selectively focusing the process on one of its layers.

To achieve this, a target layer is defined on which specific action will be taken using:

- Selective dissolution (under medium or supercritical conditions).

- Depolymerization (layers composed of polyesters or polyamides).

In this way, delamination allows:

- The obtaining of separated polymers for their subsequent recycling in high-value applications.

- The recovery of substrates in independent streams.

- The increase in the quantity and quality of recycled plastics.

-

Depolymerisation enables us to obtain monomers and oligomers from plastic waste for subsequent polymerisation to obtain high-quality plastics. This in turn enables:

- Recycling of complex fractions, such as colored packaging or non-recyclable materials.

- Obtaining high-value monomers/oligomers for the industry.

- Profitability of plastic fractions currently disposed of in landfills.

- Obtaining basic chemical products such as synthesis gas or pyrolysis oils for upgrading to industrial chemicals of interest.

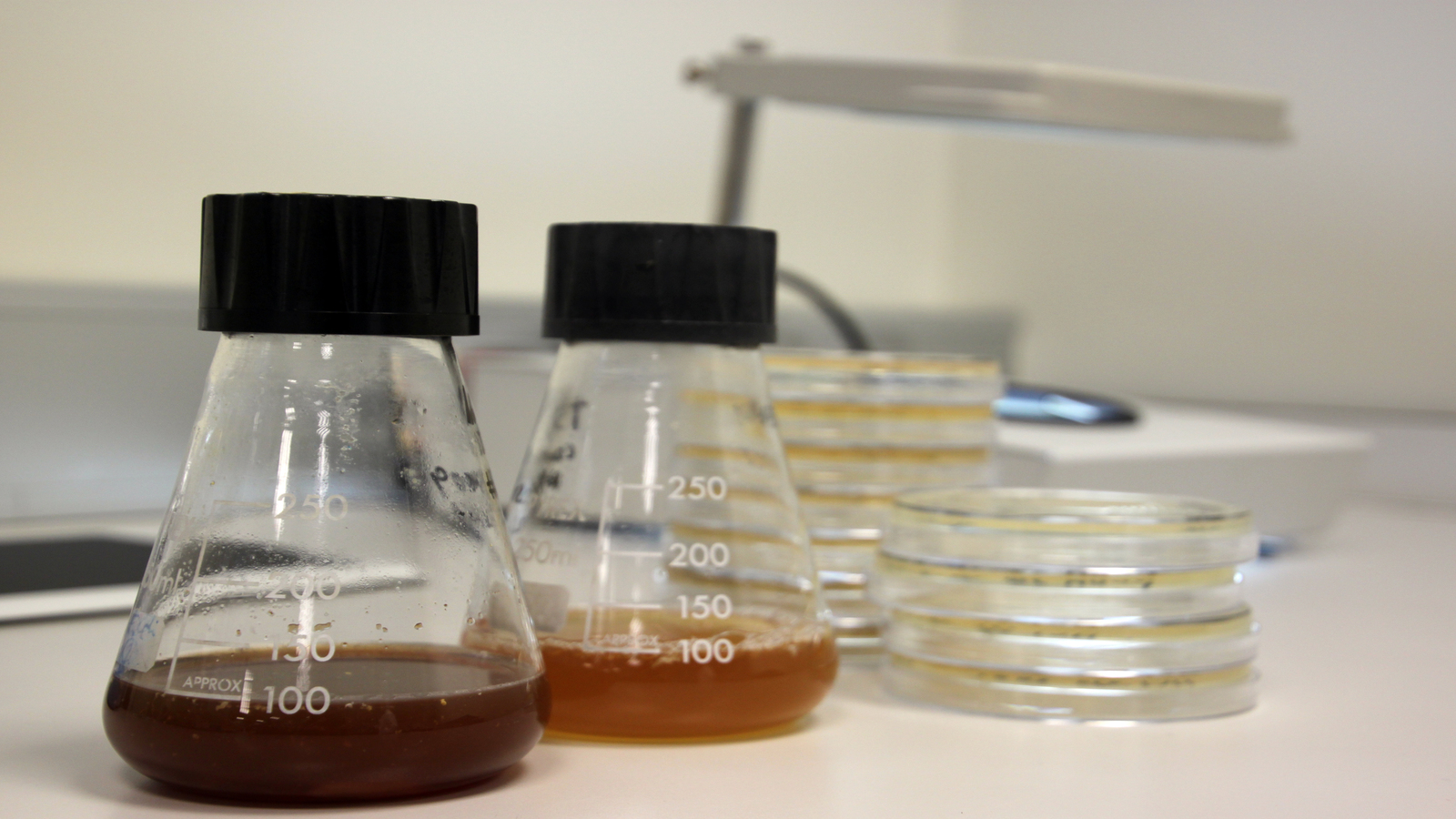

Enzymatic recycling

Enzymatic Recycling enables the depolimeryzation of plastic fractions by the action of enzymes that can break down their polymeric structure. These enzymes are characterised by high substrate specificity, which makes them a powerful tool for the treatment of complex or heterogeneous fractions due to the fact that they can act without the need for prior sorting.

Consequently, biotechnology also enables us to obtain high value-added products – including polymers with properties similar to virgin polymers – from plastic waste.

Among the advantages of this sustainable technique are:

- High specificity.

- Low energy consumption.

- Use of mild pH, pressure, and temperature conditions.

- Versatility of substrates, including the discard fraction (mixture) not suitable for mechanical recycling.

- Alignment with new circular economy models.

At ITENE, we have experience in setting up biological depolymerization processes for various plastic materials, such as multilayer (PE/PET), polymers present in mixed or reject fractions, and microplastics. Likewise, we carry out the different lines of the enzymatic recycling process:

- Identifying and developing microorganisms and/or enzymes of interest.

- Pre-treating and conditioning waste and polymers.

- Developing, validating and upscaling depolymerisation processes.

- Purifying high added-value products.

- Developing downstream product-purification processes.

-

How can I help you?

Antonio Dobón

Recycling Technologies and Waste Management Area Manager

-

How can I help you?

Rosa Doménech

Industrial Biotechnology Area Manager