CELLUWIZ: Process developments for a recyclable and compostable all-cellulose multilayer material for packaging

The CelluWiz project (2019-2022), funded by the Bio-based Industries Joint Undertaking under the European Union’s Horizon 2020 programme, aims to develop two processes able to produce an all-cellulose packaging material that can offer a competitive alternative to existing multi-layers plastic materials or multi-materials used in the packaging sector while being renewable recyclable/recycled in the paper waste value chain and biodegradable.

Context

Packaging is necessary to transport and protect food and goods and communicate with the end-user. The food packaging industry has always been agile to follow consumer expectations and societal changes. But this industry is nowadays under a great pressure from both authorities and consumers to improve its environmental and sustainability credentials in the coming years.

In this sense, there is a need for the development of a new generation of packaging that has at least the same technical performances as today’s mono or multi-materials but with a demonstrated recyclability and biodegradability.

Summary and objectives

CelluWiz overall objective is to develop two processes able to produce an all-cellulose packaging material that can offer a competitive alternative to existing multi-layers plastic materials or multi-materials used in the packaging sector while being renewable recyclable/recycled in the paper waste value chain and biodegradable. These two processes are: 1.The MFC wet lamination process and 2.The chromatogeny coating and grafting process.

To reach this overall objective, four specific objectives have been defined:

1. Develop the MFC wet lamination process. This process combines, without glue, a board with a layer of Micro Fibrillated Cellulose, creating a stratified cellulosic material. The MFC layer confers stiffness, lightweighting, barrier to air, grease, contaminants and oxygen.

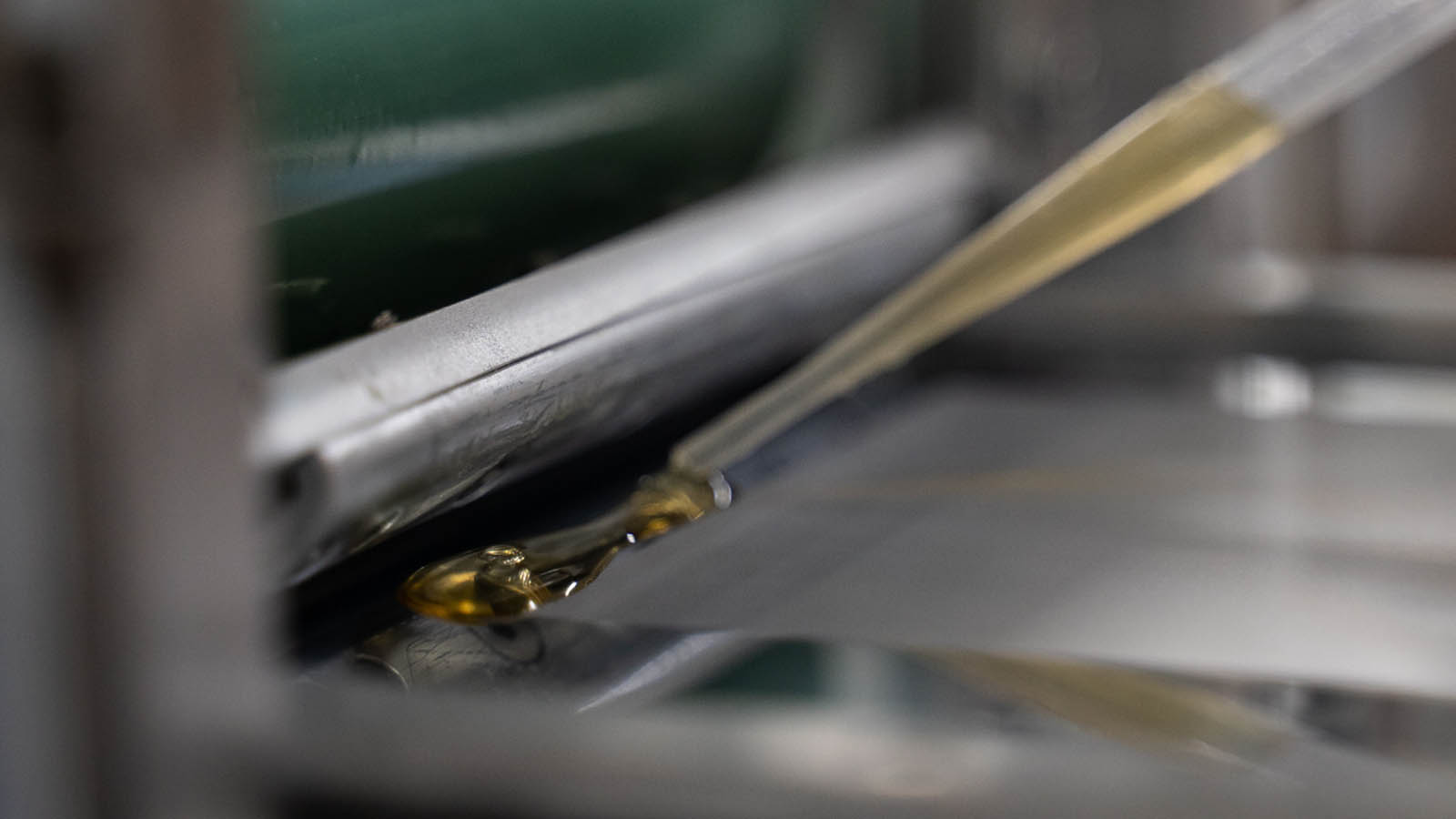

2. Develop a specific version of the chromatogeny coating and grafting process for MFC layers. This ultrafast and efficient solvent free chemical grafting process will be fully revised to create a micron size layer of pure cellulose ester which will bring liquid resistance and water vapour barrier.

3. Produce three proofs of concept (Clamshell, Cup and Tray) showing performances at least equivalent to market references.

4. Demonstrate the environmental benefits of the innovative processes and materials and their easy integration into the value chain, by performing LCA and LCC and by submitting the project advances to an advisory group composed of stakeholders of the value chain.

At the end of the project, small pilot machines will be able to prove that the CelluWiz materials can offer a competitive alternative to existing multi-layers plastic materials or multi-materials while being renewable, recyclable in the paper for recycling (PfR) value chain and biodegradable.

Consortium

A consortium of 5 partners from 4 European countries, including 3 RTOs and 2 industrial groups, has been set up to reach the objectives abovementioned:

1. Centre Technique du Papier (France)

2. ITENE – Instituto Tecnológico del Embalaje, Transporte y Logística (Spain)

3. CNRS- Centre National de la Recherche Scientifique (France)

4. Stora Enso (Finland)

5. Voith Paper (Germany)

ITENE’s role

The CelluWiz project is organized in 7 work packages (WP). The main role of ITENE, framed within WP5, is the creation of a design methodology, based on eco-design, in order to obtain the final design of the three concept tests that will be developed in the project. In addition, ITENE will select three reference products with which the properties of the proof of concept will be compared to establish the design criteria.

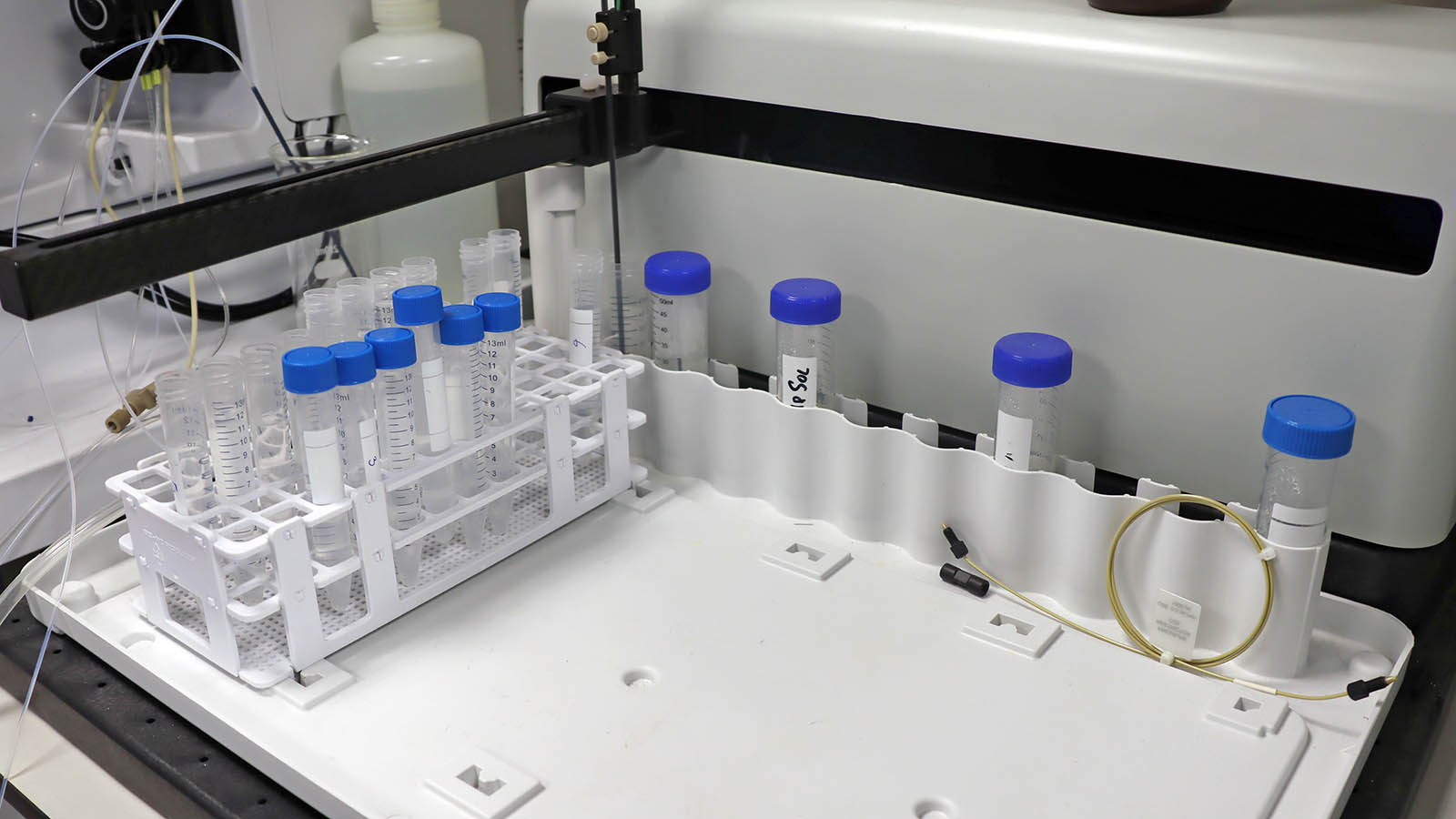

ITENE will also participate in the physical development of the prototypes by using the flat-cut plotter and will evaluate its thermal, mechanical and barrier properties. On the other hand, ITENE leads WP6, dedicated to the environmental, end-of-life and economic evaluation of the packaging solutions developed in the project. More specifically, ITENE will evaluate the marine biodegradability and compostability of materials developed under their corresponding standards (ASTM D7081 and EN 13432), and will develop the analysis of the environmental life cycle and the costs of the solutions developed to determine their potential impacts on the environment and cost estimation. Moreover, also in WP6, ITENE will be in charge of analyzing if the developed packages comply with the legislation for food contact materials.

Together with the other consortium partners, ITENE will participate in communication and dissemination activities of project results.