Sustain-a-Print (SaP): Sustainable materials and process for green printed electronics

The aim of the project is to promote the use of recycled, bio-based and biodegradable materials for the production of printed electronics as an alternative to fossil-based materials. In addition, it will introduce new safe and sustainable by design (SSbD) production routes at each stage of the printed electronics life cycle.

Context

At European level, the Circular Economy Action Plan has identified electronics and electronic equipment as a priority group of products with circularity potential, while less than 40% of electronic waste is recycled within the EU.

The analysis of new options for electronics that are designed for reuse, repair and high quality recycling must take into account several factors, such as industrial end-user specifications, life cycle analysis (LCA) and end-of-life of products.

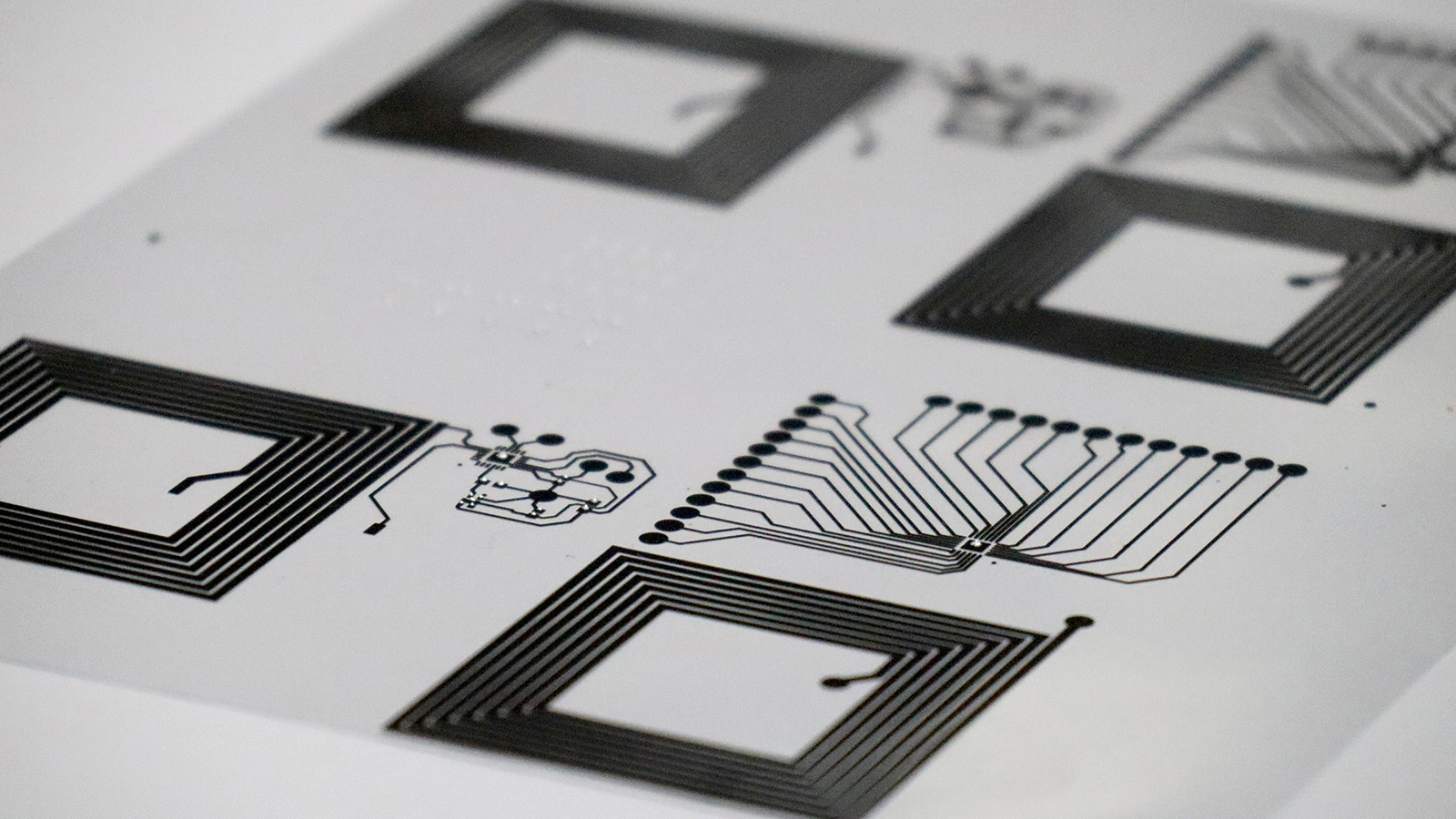

Printed electronics (PE) is an additive manufacturing method that can address these challenges and is characterized by its versatility, scalability, and low material usage, thus making it an ideal candidate for a circular production of electronics in general.

Flexible and even stretchable electronics can be obtained with this method by printing conductive and dielectric inks on flexible/stretchable substrates opening new applications in the market.

However, printed electronics products end up in landfills or incinerated after their end of life. Therefore, the main objective of Sustain-a-Print (SaP) is to open new life-cycle routes and to design and implement sustainability at every step of the life-cycle.

Summary and objectives

Sustain-a-Print aims to offer recycled, bio-based and biodegradable alternatives to materials used in the production of fossil-based printed electronics. To this end, sustainability will be designed and implemented at every step of the life cycle, including the choice of materials, their use, origin, processing, assembly and end-of-life. This work will be focused on four areas:

- Materials: biodegradable and recyclable substrate materials and functional nanomaterials (NMs) used in ink formulations will be developed.

- Environmentally friendly ink formulations and adhesives will be developed to optimise end-of-life.

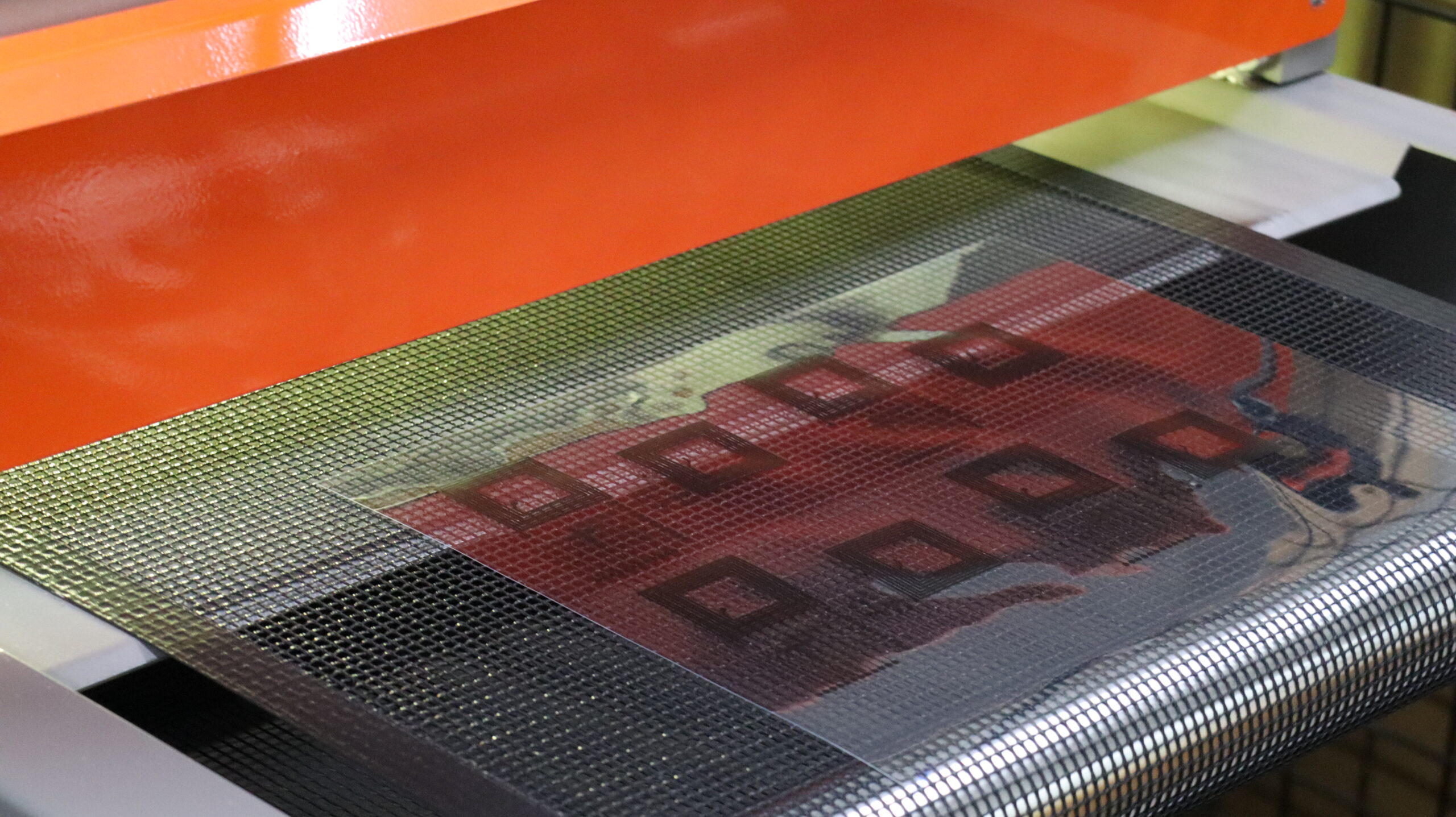

- Printing: Digital printing methods will be developed using ink formulations on substrates.

- Circular economy. Printed electronics products will be broken down and separated into smaller elements so that they can be refined into new raw materials.

In addition, Sustain-a-Print will introduce new production routes following safe and sustainable by design (SSbD) methodologies at each stage of the printed electronics lifecycle.

Two alternative life cycle routes will be researched and developed to drive the reuse or recycling of high value materials from printed electronics products: the recycling route and the biodegradable route. These routes will be demonstrated through two industrial application cases, an electrochemical biosensor and a membrane switch keyboard.

Consortium

The consortium brings together 11 partners, including 4 research centres, 6 SMEs and 1 university.

- DANISH TEKNOLOGISK INSTITUT (Coordinator) (Denmark).

- CREATIVE NANO PC (Greece).

- LOMARTOV SL (Spain).

- CENTRE FOR PROCESS INNOVATION LIMITED LBG (United Kingdom).

- UNIVERSITY OF ARISTOTELIO PANEPISTIMIO THESSALONIKIS (Greece).

- AXIA INNOVATION UG (Germany).

- INSTITUTO TECNOLÓGICO DEL EMBALAJE, TRANSPORTE Y LOGÍSTICA – ITENE (Spain).

- METROHM DROPSENS SL (Spain).

- NanoScientifica Scandinavia AB (Sweden).

- AGENCIA ESTATAL CONSEJO SUPERIOR DE INVESTIGACIONES CIENTÍFICAS (Spain).

- Melsen Tech A/S (Denmark).

ITENE’s role

ITENE will lead the work on the definition of sustainability and safety performance criteria for the products and processes developed within the project. It will also lead the definition of strategies based on the properties of the materials and processes under study in the project in order to reduce their potential impact on human health and the environment, as well as strategies to improve sustainability.

It will also participate in tasks related to the development of lignin/hybrid-based pigments, as well as to the development of dielectric inks for sustainable electronics and digital print process. ITENE will be involved in the component mounting/demounting process development, the separation of nanoparticles and components from substrate, eloping methods where solvents and chemicals to a larger extend are reused in the process and the fabrication of full system prototypes for the following demonstration activities. Moreover, the research centre will take part in the demonstration of biodegradability & recycling of printed electronics, among other activities.