Recycling technologies

Research into new mechanical, chemical and enzymatic recycling technologies enables us to overcome the current limitations to giving waste a second life.

At ITENE we work with innovative companies and international consortiums to develop technologies that are already revolutionising the way we recycle waste to transform it into new products. Our ultimate goal is to make the circular economy model, to which we are fully committed, a reality.

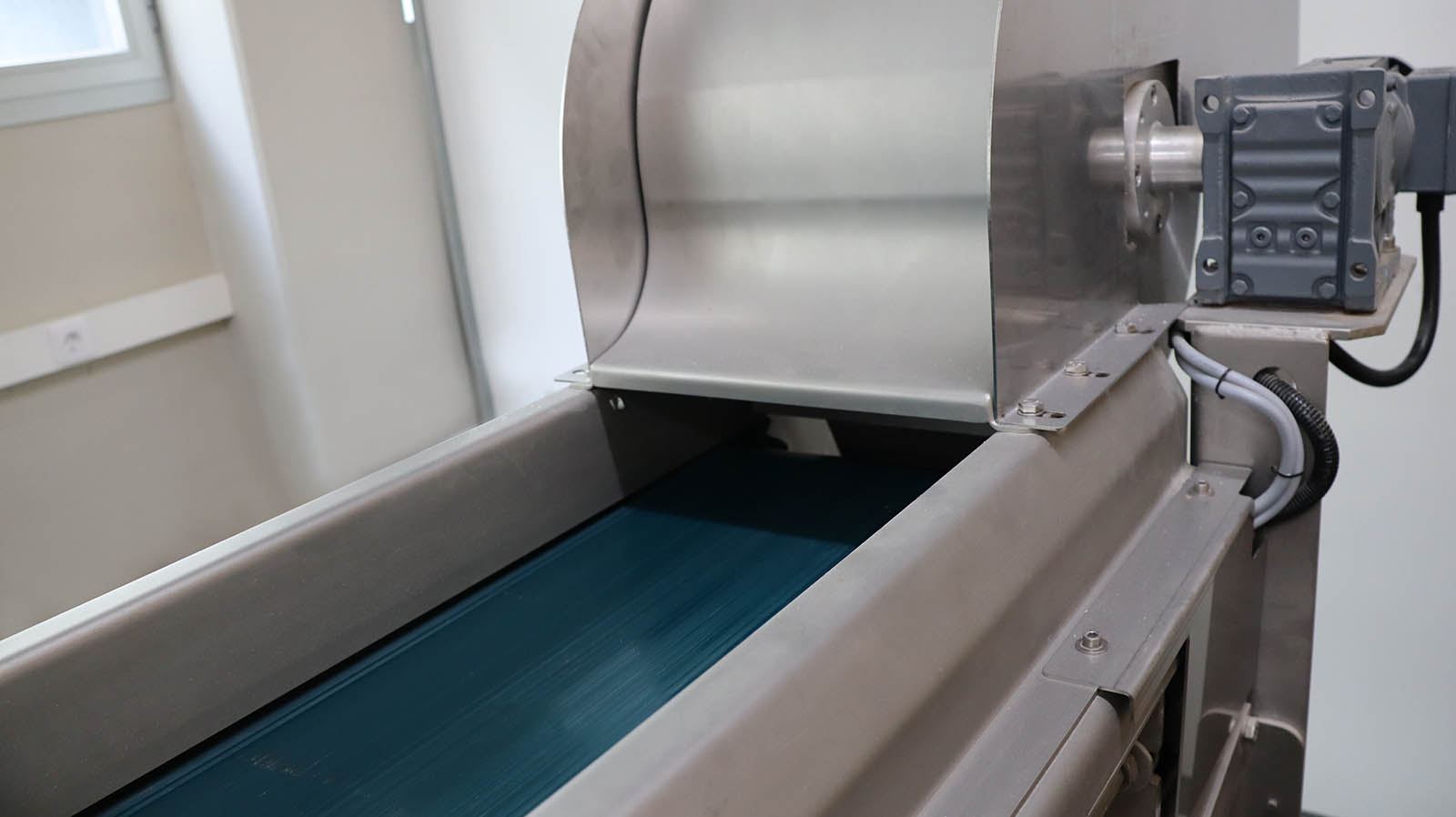

Mechanical recycling

Mechanical recycling generally consists of shredding plastic waste, washing it, separating the contaminants or impurities it contains and inserting it into an extruder to obtain recycled pellets.

This process may be restricted by the presence of contaminants or multilayer structures, degradation of the materials (as a result of recycling itself), their use or their lack of homogeneity.

Strategies based on additive incorporation and reactive extrusion are currently used to address these difficulties and improve the properties of plastic waste. Consequently, dispersion of additives in the plastic material plays a key role in achieving ideal properties.

Even so, the options are limited when it comes to highly heterogeneous, degraded and/or contaminated recycled materials, which means that their use is mainly reduced to low value-added applications.

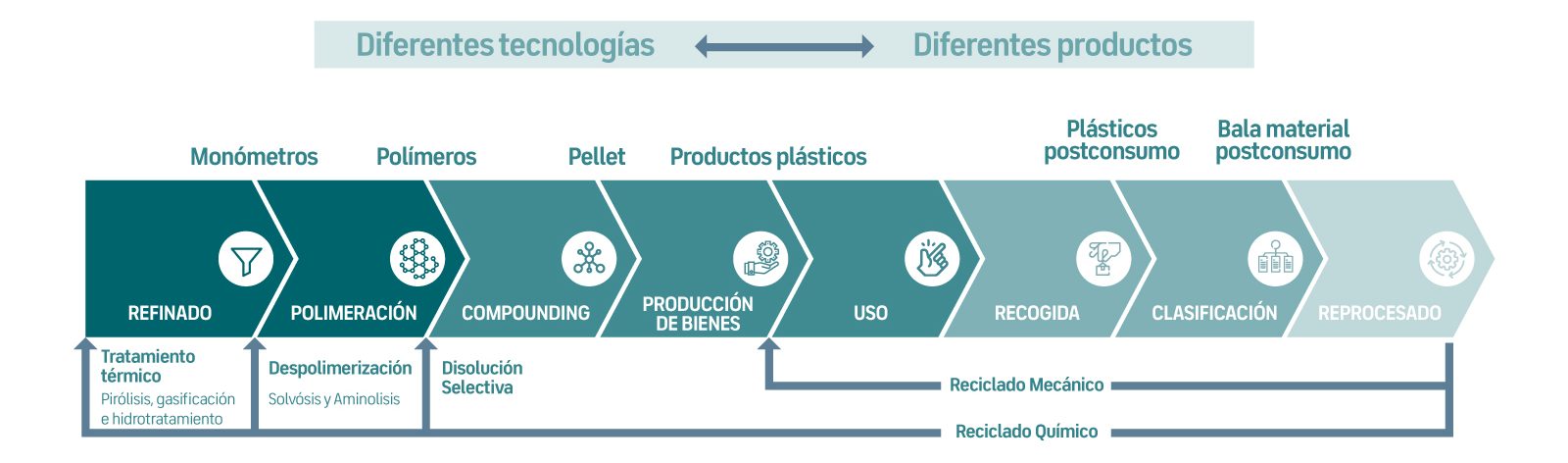

Chemical recycling

Complementary to mechanical recycling, chemical recycling enables the exploration of diverse recycling routes and processes tailored to handle the most challenging value-added fractions currently available. It employs techniques focused on the selective breakage of the polymer chain through solvolysis depolymerization processes, recovering the original monomers.

Alternatively, it involves the chemical valorization of plastic materials via pyrolysis and gasification, followed by upgrading into products of interest for the chemical industry.

At ITENE, we focus on:

- Developing chemical depolymerization processes to obtain products of interest for the plastics and chemical industries from currently unutilized fractions. This enables:

- The recycling of complex fractions, such as coloured packaging or materials that cannot be mechanically recycled.

- Obtaining high-value monomers/oligomers for industry for subsequent polymerisation and obtaining polymers of similar quality to virgin polymers.

- Making plastic fractions currently disposed of in landfill sites profitable.

- Obtaining base chemical products such as synthesis gas or pyrolysis oils for upgrading to chemical products of industrial interest.

Enzymatic recycling

Enzymatic recycling consists of treating non-recycled plastic fractions by the action of microorganisms, insects or enzymes. In particular, enzymatic recycling enables depolymerisation of unrecycled plastic fractions by the action of enzymes that can break down their polymeric structure.

In recent years, several enzymes capable of attacking various polymers such as PET and polyurethane have been developed, although efforts are increasingly focused on developing biological catalysts to treat other fractions such as polyamides and polyolefins.

Advantages of enzymatic recycling

- Due to the enzymes’ acute substrate specificity, this technology constitutes a powerful tool for treating complex or heterogeneous fractions, i.e., fractions that contain various problematic components, by enabling depolymerisation of a particular polymer without the need to perform complex pre-treatment in order to be able to classify them.

Enzymatic or biotechnological recycling enables us to overcome the limitations of mechanical and chemical recycling by enabling the following processes:

- treatment of multilayer materials.

- treatment of polymers present in mixed or rejected fractions

- treatment of microplastics

2. Low energy consumption is another advantage of this type of process, since it takes place in mild temperature and pH conditions (within the biological range). Finally, the process always takes place in water-based media which means that its environmental impact is negligible.

- Consequently, biotechnology also enables us to obtain high value-added products from plastic waste, including polymers with properties similar to virgin polymers.

-

Can I help you?

Antonio Dobón

Recycling Technologies and Waste Management Area Manager

-

Can I help you?

Rosa Doménech

Industrial Biotechnology Area Manager