New biological and chemical processes allow recovery of PET plastic waste that presents difficulties in the recycling process

- The ITENE research centre has developed advanced enzymatic and chemical depolymerisation processes for monolayer, multilayer and coloured packaging waste in the RecyPET project, financed by IVACE with Feder funds.

The ITENE research centre has developed new biological and chemical processes that allow the recovery of multilayer, monolayer and coloured PET (polyethylene terephthalate) plastic packaging waste that presents difficulties for mechanical recycling or that is not currently recycled.

This research has been carried out between June 2022 and June 2023 in the RecyPET project, financed by IVACE (Instituto Valenciano de Competitividad Empresarial) with Feder funds.

The project manager at ITENE, Antonio Dobón, has highlighted that “the developed processes contribute to achieve the circular economy objectives established at European and national level through the reduction of waste incinerated or deposited in landfills and its valorisation to be used to obtain new raw materials reintroduced in the value chain”.

In particular, the recycling boost is in line with the Spanish Royal Decree on Packaging and Packaging Waste, which sets a target of introducing at least 25% recycled plastic in PET packaging by 2025. In addition, the recycled content in packaging represents a pathway to achieving exemption from the Spanish virgin plastic tax that came into force in January, in accordance with the Waste and Contaminated Land Act for a Circular Economy.

Advanced depolymerisation processes

The research carried out at RecyPET has focused on offering an alternative to mechanical recycling for PET fractions that are not currently recycled by these methods. To this end, as the researcher explained, “first of all, the PET value chain was analysed to detect those types of PET that are not recycled mechanically and which had a potential for use”. Coloured bottles, residual PET recycling fractions and multilayer materials were identified as waste of interest.

To boost their recovery, an enzymatic or enzyme-based depolymerisation process and a chemical depolymerisation process were developed.

The first one was a biological depolymerisation process whereby microorganisms have been identified with the ability to produce enzymes that, in turn, degrade PET waste. In addition, to improve the process, microorganisms with the greatest capacity to produce enzymes selective to PET degradation have been selected.

Specifically, these enzymes allow PET to be degraded, breaking it down into TPA (terephthalic acid), a monomer that can be used to generate new recycled PET, as well as in other applications, such as paints, varnishes, cosmetics, etc.

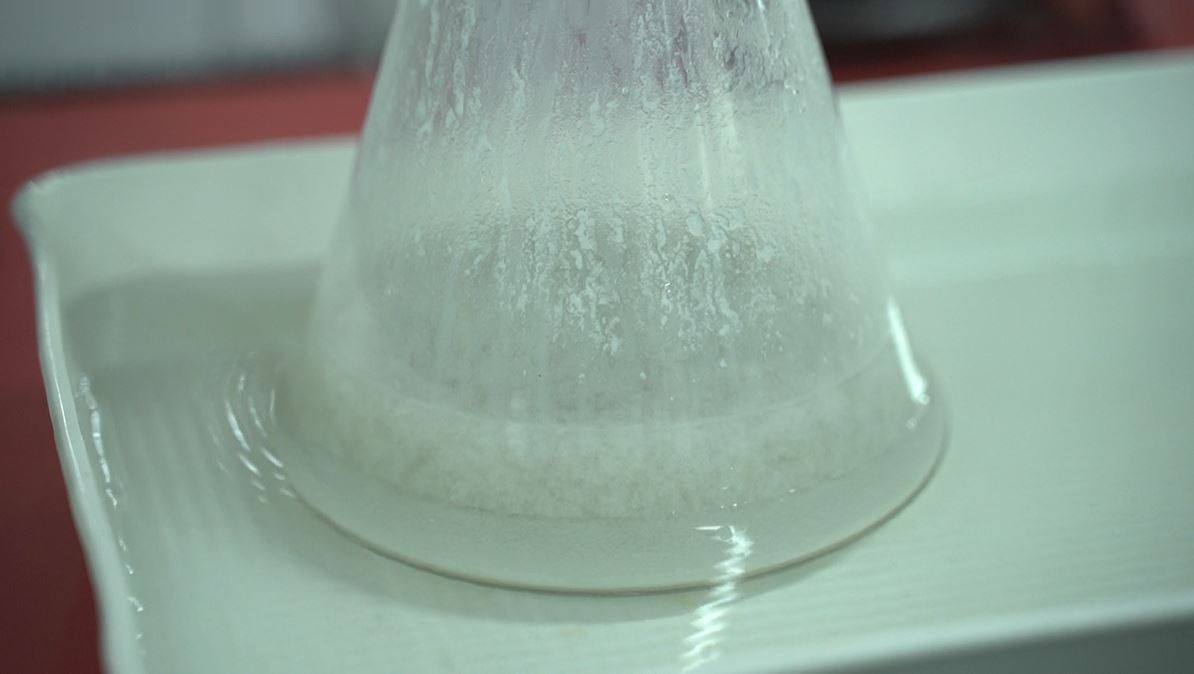

On the other hand, a chemical depolymerisation process has been developed to achieve the decomposition of the plastic. For this purpose, a chemical process (solvolysis) has been carried out with ethylene glycol, a chemical compound that, in a liquid state and together with catalysts, allows the decomposition of PET into a monomer, BHET (bis-2-hydroxyethyl terephthalate). This monomer can be used as a precursor to make new recycled PET as well as in applications in the paint and varnish sector.

In this chemical depolymerisation process, which lasts between 1 and 2 hours, very high yields of close to 98% have been achieved. This means that 98% of the PET can be broken down into BHET by means of this chemical depolymerisation. Furthermore, after a pilot scale-up, it has been proven that up to 700 grams of BHET can be obtained in a reactor for each kilo of PET processed.

This research is part of the line of work carried out by ITENE to develop technological solutions to help the packaging value chain to meet the different sustainability objectives, including increasing the percentage and quality of recycled packaging materials.